The Future of Quality Management: Centralized, Custom, Digital

Running a business means juggling many moving parts like crews, materials, deadlines, and budgets. In the rush, quality management can sometimes slip down the priority list, especially if your current system is a patchwork of paper forms and spreadsheets. Many companies have quality programs that exist only on paper, gathering dust in a binder or scattered across shared drives. If that sounds familiar, it might be time to ask the big question: Do you need a digital upgrade for your Quality Management System (QMS)?

Signs It's Time to Go Digital

How do you know when your quality management approach needs a modern upgrade? If you're drowning in paperwork, each team has its own way of working, or you only discover issues during audits and customer complaints, it's a clear sign your program might need a digital boost.

In fact, more than half of companies today have transitioned away from purely paper-based quality systems to digital QMS software. Forward-thinking teams are making the switch to stay ahead of the curve. By swapping binders and spreadsheets for a software-based QMS, you can streamline quality management. Documents get digitized, workflows automated, and every action becomes more traceable and audit-ready.

All Your Quality Tools in One Place

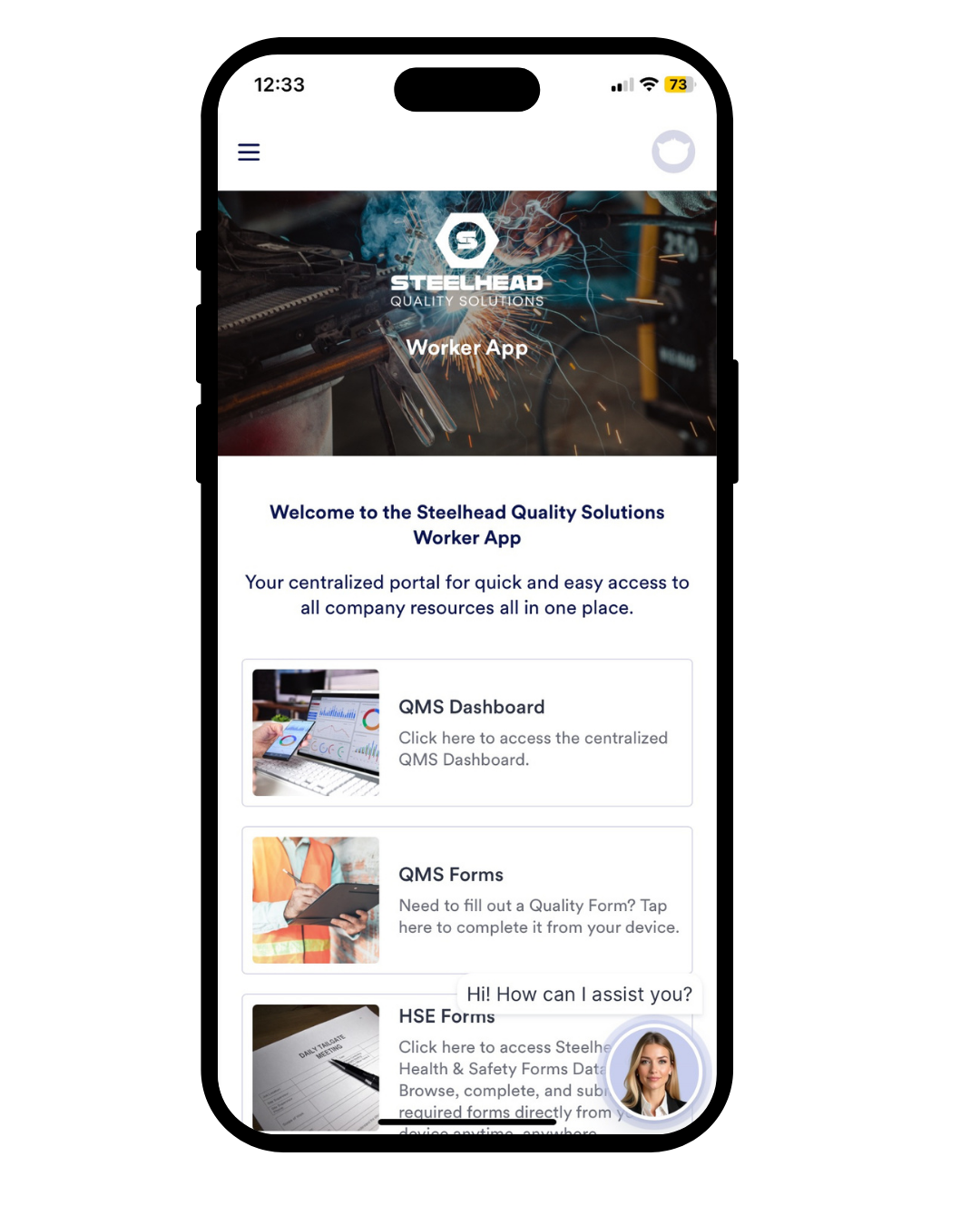

One of the biggest advantages of a digital upgrade is having all your quality tools in a single portal. Rather than jumping between different software (or piles of paper), your team can go to one hub for everything they need. For example, a custom app or dashboard that includes:

QMS Dashboard: A centralized dashboard where you can see key quality metrics at a glance (inspection status, open issues, upcoming audits).

Digital Forms (Quality & HSE): All your quality and HSE forms are accessible on any device. The crew can pull up the latest version of a form in the field, complete it on a phone or tablet, and submit it instantly.

Workhub for Compliance: A link to Workhub where employees can log in to complete required training, policy acknowledgments, and certificate tracking for HSE and quality. Workers can review policies, complete training, and update certifications, all in one place. Managers see everyone's compliance status at a glance.

Document Library: A searchable library for all your key documents—your Quality Manual, HSE manual, standard operating procedures, and work instructions. No more thumbing through binders – anyone on-site can pull up the latest version of a document and know it's current.

Having these tools under one digital roof means nothing is out of reach. Your team in the field has the same information as the folks in the office. When a procedure gets updated, everyone sees the new version immediately. When someone submits a quality form from a jobsite, managers at headquarters can review it in real time. Everything is organized, up-to-date, and available on demand.

No One-Size-Fits-All: Tailored Digital Solutions

Every company’s workflow is different, so quality software should adapt to your way of doing things, not vice versa. That’s why our approach at Steelhead is to build custom digital quality tools for each client.

We digitize your existing forms and processes, preserving the terminology and steps your team already knows. Need specific data fields or approval steps? No problem, we build them right into the workflow. Everything from the portal layout to dashboard metrics (even your company branding) is configured to match your needs.

This custom-fit philosophy sets us apart. Many providers hand you a one-size-fits-all package or just a binder of documents, but we deliver a tailored digital platform alongside the quality program. The result is a QMS that fits like a glove. And when a quality system aligns with how your team actually works, they will use it consistently – so your program won't end up just gathering dust on a shelf.

Quality at Your Fingertips, In Real Time

The true power of a digital QMS is making quality management happen in the moment, not hours or days later. Quality is officially in the field now — not confined to the office or an audit day. With a well-designed mobile-friendly system, your crew can perform quality tasks right on the jobsite as part of their normal routine:

On-site issue capture: If someone finds a defect or safety hazard, they can pull out their phone, open the app, and flag a quality issue immediately. They can even upload photos and notes from the field on the spot.

Instant submission of forms: Whether it's a welding inspection form or a safety checklist, once it's filled out on a device and submitted, the data is instantly available to managers. No waiting for paperwork to be turned in or transcribed.

Real-time notifications: Managers can receive instant alerts when a non-conformance report is filed or if a critical inspection fails. This means faster response times – you know about issues right away and can take action.

All of this adds up to a more proactive quality management culture. Issues caught and addressed early mean fewer surprises later. Your team in the field feels empowered to own quality outcomes because the tools make it easy. Meanwhile, management gets a live window into what's happening across all sites, without having to chase people for updates. In other words, no more chasing papers or backtracking through email chains, just clear, consistent quality control.

Embrace Your Digital Upgrade

A quality management system should be more than a dusty binder of procedures; it should be the engine driving continuous improvement. If your current system isn’t doing that, it’s probably time for a digital upgrade. The good news is, you don’t have to start from scratch or settle for a one-size-fits-all software to make it happen. You can keep the best parts of what you have and modernize it.

At Steelhead, we specialize in helping companies bridge that gap. We’ll work with you to transform your existing quality program into a digital, user-friendly powerhouse that actually gets used day-to-day. Whether your goal is to reduce rework, win bigger contracts, improve safety performance, or simply make life easier for your team, a tailored digital QMS can be a game-changer.