Insights on Quality, Inspections, and Industrial Execution

The Steelhead Quality Solutions blog explores practical strategies for QA/QC, quality management systems (QMS), inspections, asset integrity, and project execution. We share real-world insights from the field to help teams reduce rework, improve compliance, and build quality systems that actually work.

Categories

- Audit & Compliance

- Business Strategy

- Continual Improvement

- Digital & Modern QMS

- Document Control

- Fractional Quality Management

- Nonconformance & CAPA

- Process Improvement & Mapping

- QMS Fundamentals

- Quality Management

- Quality Metrics & Performance

- Safety & Operational Excellence

- Supplier & Vendor Quality

NCRs That Get Closed: Writing Nonconformance Reports That Drive Action

Stop writing NCRs that stall, and start writing reports that make the next decision obvious, fast, and easy to close.

What Does “Continual Improvement” Actually Mean?

Confused about “continual improvement” in ISO 9001 versus other forms of process improvement? This quick breakdown makes the difference clear and shows how to build improvement into your QMS for long-term results.

From Complaints to Improvements: Leveraging Customer Feedback for Quality

Turn customer feedback into a clear quality advantage by spotting trends early, fixing root causes, and showing clients their input leads to real improvements.

Why Process Mapping Is a Hidden Quality Superpower

Process mapping turns your day to day workflow into a clear picture, so you can spot hidden delays, prevent quality escapes, and strengthen your system fast.

Quality Management Trends to Watch in 2026

Quality management is changing fast, and 2026 will reward the teams who get ahead of digital QMS, virtual audits, stronger supply chain oversight, and the push to align quality with sustainability before issues hit the floor.

Quality Assurance vs Quality Control: What’s the Difference?

Quality Assurance builds the process right and Quality Control checks the results. When you understand how these two roles work together, your entire quality system becomes stronger, clearer, and far more effective.

The 7 Basic Quality Tools: Your Quick Guide to Better Problem Solving

A simple set of seven tools can turn everyday quality problems into clear data-driven insights that lead to real improvement.

From Reactive to Proactive: Embracing Risk-Based Thinking in Quality

A proactive quality culture begins with simple habits that prevent problems before they appear. By embracing risk based thinking and using practical tools to identify and manage risks teams can reduce surprises, strengthen processes and create a smoother path to continuous improvement.

Quality Is a Team Sport: Engaging and Training Your Workforce for Excellence

In the end, quality isn’t a department. It’s a culture. And the most successful companies are the ones where everyone, from the shop floor to the boardroom, plays on the same team.

Fixing the Root Cause: 5 Steps for Effective Corrective Action

True efficiency is not about working faster, it’s about solving problems so well that they never return.

Quality Starts at the Top: The Role of Leadership in Quality Management

True quality starts with leadership—when those at the top model commitment, accountability, and integrity, the entire organization follows their lead.

Quality Metrics That Matter: 5 KPIs to Drive Improvement

Are your quality metrics actually helping you improve—or just filling up dashboards? Discover the five KPIs that can uncover waste, boost performance, and drive real results.

Quality-First Culture: Getting Everyone on Board

Is quality just a department—or is it something every employee lives out, every day? The difference could transform your entire operation.

Quality Management Myths, Busted!

Quality management is not a cost or a constraint—it is a competitive advantage. When myths are replaced with facts, teams perform better, customers stay loyal, and operations become stronger from the ground up.

What Qualifies as an Effective QMS Audit? Internally and by Third Parties?

An effective QMS audit goes beyond ticking boxes. Whether internal or third-party, the best audits uncover root causes, strengthen processes, and drive continuous improvement, turning compliance into real value.

No More Band-Aid Fixes: How Root Cause Analysis Solves Quality Problems for Good

Quick fixes don’t solve quality problems; they just hide them. Root Cause Analysis digs deeper to eliminate issues for good, saving time, money, and frustration.

A Good Procedure Should Pass This 5-Second Test

If your procedures take more than five seconds to understand, they’re too complicated. Learn how the 5-second test can transform SOPs into clear, practical tools your team will actually use.

When should an Alberta-based firm choose fractional quality support?

Not every Alberta firm needs a full-time quality manager. Discover when fractional quality support is the smarter choice, giving you expert oversight exactly when you need it.

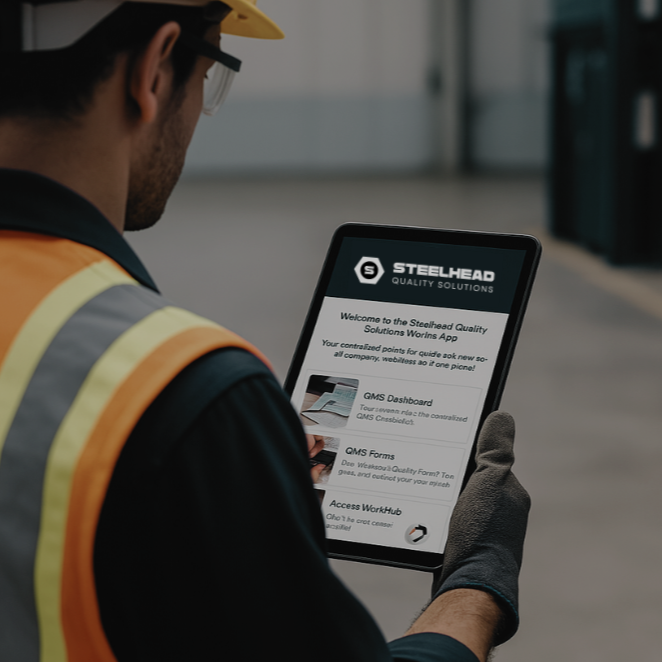

The Future of Quality Management: Centralized, Custom, Digital

Is your quality program still stuck in binders and spreadsheets? Discover why forward-thinking companies are moving to centralized, custom digital systems that put quality at everyone’s fingertips.

The Cost of Poor Quality: Why Investing in a Quality Management System Saves Money

Rework and delays aren’t just frustrating—they’re profit killers. The right Quality Management System keeps money in your pocket.